“Innovation in Automation and Energy, with a Vision for a Green and Sustainable Future”

“Innovation in Automation and Energy, with a Vision for a Green and Sustainable Future”

Houshmandkaran Sahel Khazar Company was established in 2012 (Registration No. 12025) with the mission of providing services in the fields of electrical engineering and automation to both public and private sector clients.

Leveraging a team of experienced engineers and a wealth of knowledge and expertise, the company has successfully carried out extensive projects in areas such as:

Power distribution

Industrial and residential automation

Commissioning of factory production lines

Installation and operation of IP surveillance cameras

Fire alarm systems

Design and implementation of electrical panels

Expanding activities in key resource sectors

Becoming a modern organization aligned with international standards

Achieving excellence in workforce retention and enhancing employees’ quality of life

Expanding operations and providing services to neighboring countries

Active participation in major civil and infrastructure projects

Obtaining international standard certifications

Delivering services of the highest quality in the shortest possible time

Commitment to all legal and contractual obligations while ensuring client satisfaction

Prioritizing employee safety under all circumstances

Protecting the environment and preventing its degradation

Preserving human dignity of employees and their families while supporting professional development

Embracing innovative ideas and fostering creativity

Since 2016, under a formal agreement, the company has been responsible for the preparation, repair, and maintenance of electrical and mechanical installations for Sari Municipality.

This has included:

Designing installation plans for urban development projects

Supervising proper implementation of electrical systems

Maintaining electrical and elevator systems in municipal office buildings

Troubleshooting and repairing public lighting infrastructure

Maintaining water pump systems across urban streets

In addition, over the past decade, the company has successfully executed numerous contracts with private clients, corporations, and government agencies. Selected projects include:

Commissioning of the polymer pipe and fittings production line – Sadaf Polymer Mahshahr Shomal

Commissioning of polyethylene pipe and fittings production line – Khazar Kaveh Gostar Morvarid

Commissioning of clay brick and roofing tile production line – Behshahr

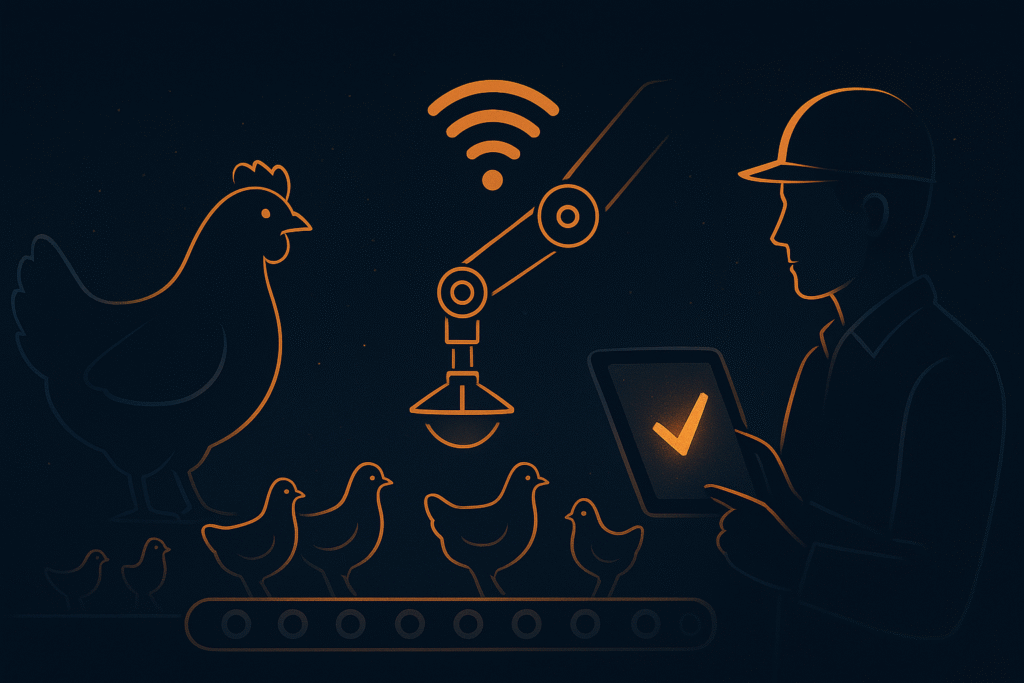

Automation and smart farming systems – Mr. Zamani (Parent Poultry Farm)

Automation and smart farming systems – Mr. Tabari (Broiler Poultry Farm)

Automation and smart farming systems – Mr. Alipour (Broiler Poultry Farm)

Automation and smart farming systems – Mr. Izadiar (Broiler Poultry Farm)

Power distribution – Payam Noor University, Behshahr

Power distribution – Bozcheft Forest Park, Babol (Phase I)

Power distribution – Abbas Abad Tourism Area, Mazandaran

Power distribution – Tabarestan Steel Factory, Savadkuh

Replacement and repair of transmission line connections – Hezar Jarib, Behshahr

Optimization of rural power networks – Galugah

Expansion of rural power networks – Dasht Village (Phases I & II)

Optimization of rural power networks – Northern and Southern Villages of Behshahr

Maintenance of electrical networks – Rostamkola & Zaghemarz (2013–2015)

And dozens of other major projects…

01

Ability to identify different types of electrical faults

Study of electric current passing through the human body and types of electric shock

Methods of preventing electric shock

Grounding (Earthing) systems and their implementation principles

Protection of electrical networks and equipment

02

Types of fuses and their applications in electrical networks

Types of protective relays and their applications

Types of protective devices

Fire alarm and intrusion detection systems

Closed-Circuit Television (CCTV) systems

Control and power circuit equipment

03

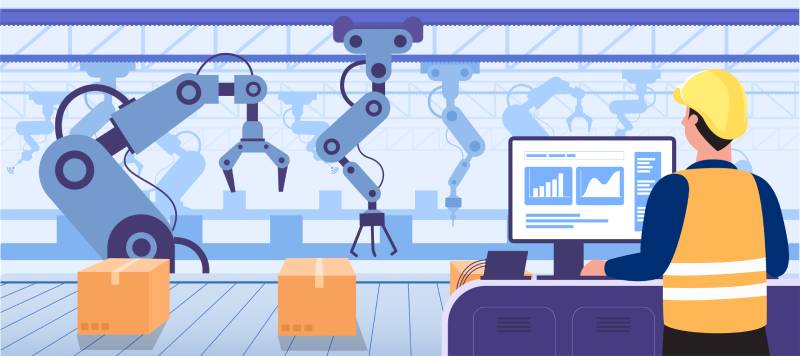

The Industrial Electrical Division of Houshmandkaran Sahel Khazar Company provides a comprehensive range of services, including:

Design and implementation of simple and advanced industrial electrical panels

Design and installation of capacitor banks

Design and construction of electrical distribution panels and substations

Electrical system design and implementation for factories, greenhouses, boiler rooms, and cold storage facilities

Design and construction of metering panels approved by provincial power distribution authorities

Design and execution of factory automation systems

Supply and sales of industrial electrical equipment, including:

Disconnectors, sectionalizers, air circuit breakers, compact circuit breakers, and miniature circuit breakers

Contactors, inverters, drives, and soft starters

Wires, cables, and related accessories

Cable organizers and management systems

Structures for wall-mounted and free-standing panels

Lighting poles, lamps, and illumination systems

Other electrical equipment and accessories

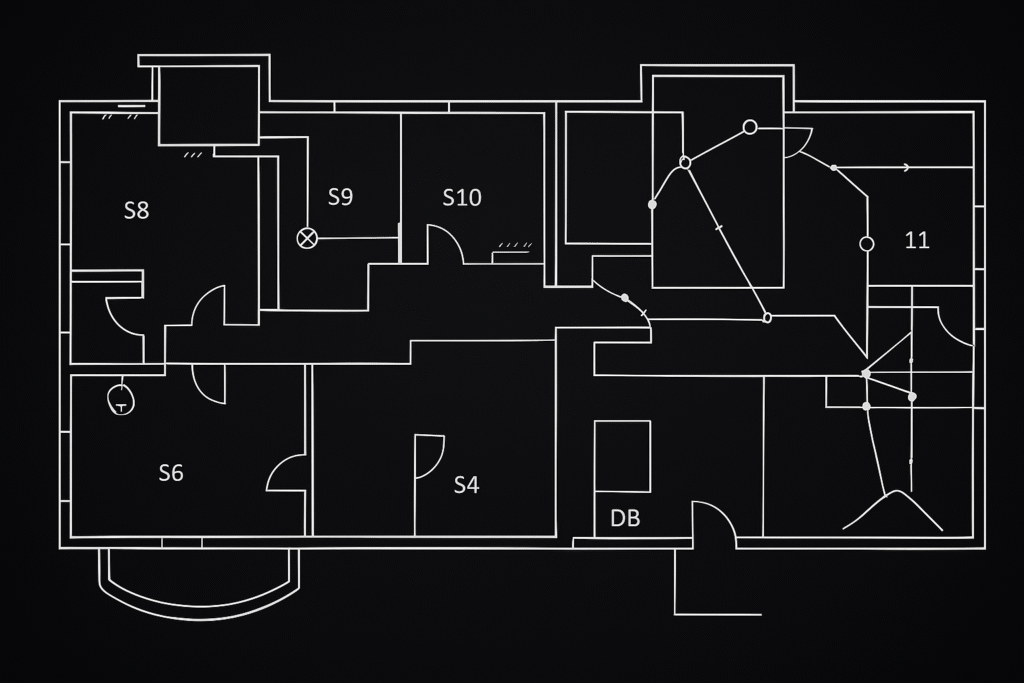

The main electrical panel is the starting point of any building’s electrical wiring system. It includes the main switch, fuses, and protective devices that control the flow of electricity throughout the entire building. Proper and precise installation of the panel ensures both safety and reliable performance of the system. Easy access to switches during emergencies is also of great importance.

Key Guidelines:

The panel should be installed in an accessible location.

Fuses and switches must be selected according to the load capacity.

Circuits should be clearly labeled and identified.

Main cabling is the pathway that transfers electricity from the main panel to different points throughout the building. The quality of the cables and adherence to standard routing are essential to prevent hazards and voltage drops. The use of conduits and protective channels enhances system safety and protects the cables from potential damage.

Key Guidelines:

Cables must be selected according to proper standards and quality requirements.

Cable routes should be kept away from moisture and heat sources.

Cable length and routing must be carefully planned.

Switches and sockets are the final connection points that deliver electricity to end users, making their proper installation highly important. Appropriate height and spacing ensure safety and convenience, while secure cable connections and compliance with standard colour codes reduce potential risks.

Key Guidelines:

Installation height must comply with standard requirements.

The spacing of sockets and switches should be practical and user-friendly.

Connections must be secure and follow standard wiring practices.

Connecting lighting and electrical equipment is a critical stage in building electrical systems. Proper wiring, adherence to safety standards, and accurate load distribution ensure efficiency, durability, and user safety.

Key Guidelines:

Lighting fixtures and equipment must be connected according to approved wiring diagrams.

Connections should be made using certified materials and standard practices.

Load distribution must be carefully calculated to prevent overloading and ensure system reliability.

Grounding (earthing) is one of the most essential measures in building electrical systems to ensure safety and prevent electrical hazards. A properly designed and implemented grounding system protects both people and equipment by safely directing fault currents into the ground.

Key Guidelines:

Grounding systems must be implemented according to international standards.

All connections should be secure, durable, and regularly inspected.

Protective equipment and safety protocols must always be observed during installation and maintenance.

Final inspection and testing are critical steps to ensure the safety, reliability, and proper functioning of building electrical systems. Thorough testing verifies that all components are installed correctly, operating as intended, and compliant with safety standards.

Key Guidelines:

Perform comprehensive checks of all wiring, connections, and equipment.

Verify that protective devices, switches, and circuits operate correctly.

Ensure compliance with relevant electrical codes and standards before system handover.

A Building Management System (BMS) is an integrated management platform for a building, encompassing systems such as HVAC (heating, ventilation, and air conditioning), fire detection and suppression, access control, CCTV surveillance, lighting, and more. The BMS collects data from each zone or space and provides it to a centralized monitoring and supervision system.

The goal of a smart building management system is to leverage control technologies to manage a building’s resources and events according to its specific use (residential, office, commercial, etc.). Implementing BMS reduces the impact of human errors, unforeseen events, and incidents, while increasing the reliability of building systems and equipment and enhancing overall building security.

Intelligent access and traffic control in the building

Intelligent control of lighting, temperature, humidity, and other environmental parameters

Automatic shutdown of lighting when rooms are unoccupied

Automatic shutdown of electrical appliances when not in use

Restriction on the use of telephone, gas, water, electricity, etc.

Alerts for open doors, windows, curtains, etc.

Protection of the building and occupants against fire, gas leaks, etc.

Building security against theft (alarms or CCTV surveillance)

Remote control of electrical appliances (via phone)

Intelligent irrigation control

Smart audio system

The Houshmandkaran Sahel Khazar Engineering Group, leveraging experienced specialists, is capable of commissioning production lines, as well as developing, repairing, and maintaining industrial lines.

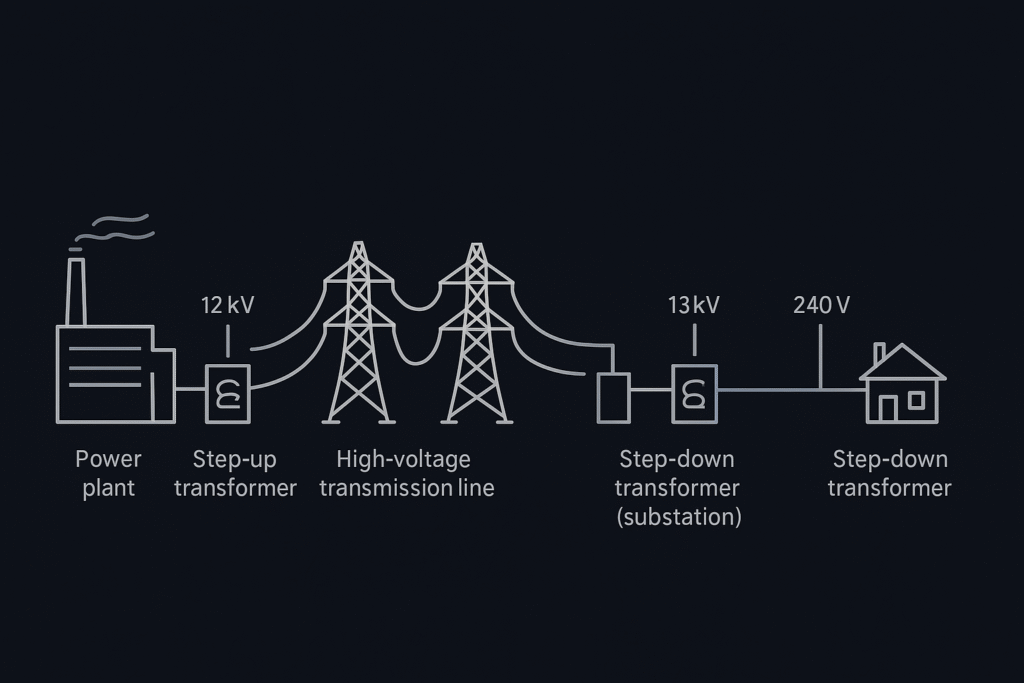

With the expansion of urban and rural areas, existing electrical networks must also be developed and extended. This company, utilizing skilled engineers and experienced technicians, is fully prepared to execute power supply and network expansion projects.

Since 2012, numerous projects in power distribution, fault diagnosis, and distribution network development have been carried out by the engineers of this group.

Capabilities in the Power Network Sector:

Design, supply, and construction of low- and medium-voltage power distribution networks

Rehabilitation and optimization of existing distribution networks

Maintenance and installation of lighting networks

Implementation of electrical installations for factories and buildings

The Houshmandkaran Sahel Khazar Engineering Group, leveraging experienced specialists, is capable of commissioning new production lines and developing existing operational lines. All stages of work are meticulously planned, engineered, managed, and executed.

Proper and flawless installation and commissioning of machinery are crucial for ensuring uniform production and preventing stoppages in the production line.

This approach guarantees maximum utilization of purchased equipment, reduces production time, lowers manufacturing costs, and increases profit margins.

Upon the arrival of your production line or equipment at the factory, the following operational activities will be carried out:

Deployment of experienced technicians for machinery installation, commissioning, and maintenance

Training employees and machine operators on proper usage of equipment

Providing continuous technical assistance and support

Assisting and training staff to develop machinery maintenance and service programs

01

Outdoor temperature and humidity

Temperature at multiple points inside the barn

Indoor humidity

Carbon dioxide (CO₂) levels

Ammonia (NH₃) levels

Air pressure

Poultry weight

Display of dust levels inside the barn, wind speed over the poultry, and water consumption within the barn

02

Equipment Controlled by the System:

Alarm sirens

Heaters

Lighting

Foggers / Misters

Inlet vents

Air entry curtains

Cooling water pumps

Wall-mounted fans on the barn’s short walls (tunnel fans)

Wall-mounted fans on the barn’s long walls (minimum ventilation fans)

Fan control can be implemented via simple on/off switching or speed control through inverters.

Lighting control can be implemented via on/off switching or intensity control using dimmers.

03

High-accuracy sensors

Locally manufactured (Iranian) with cost-effective services

Low price and high quality

9-inch color touchscreen display

Multiple user levels with separate access permissions

Automatic alarms triggered by any malfunction in control equipment, 24/7

Suitable for broiler, parent, and laying hen farms

Connectivity to computers and mobile monitoring

Ability to receive barn data via SMS

Graphical representation of temperature, humidity, and gas levels in the barn

Various control methods for air inlets and fans

Display of any changes in device settings and personnel management

Easy and quick installation

04

Reduced energy consumption

Easy maintenance of all hardware and software equipment by system users

Design and manufacture of all installed equipment according to poultry industry standards

Elimination of all mechanical actuators, including thermostats, etc.

Replacement with intelligent electronic actuators

Improved production quality through precise control of temperature and humidity

Reduced worker traffic inside barns, preventing virus transmission from humans to poultry

High security and reliability of all proposed equipment

Recording and storing all data in computer memory and on device memory cards

Reduction of human error

Increased efficiency, production, and profitability

Reduced poultry farm losses

Reduced labor requirements and associated costs

Reduction of fuel and energy consumption by up to 70%